Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

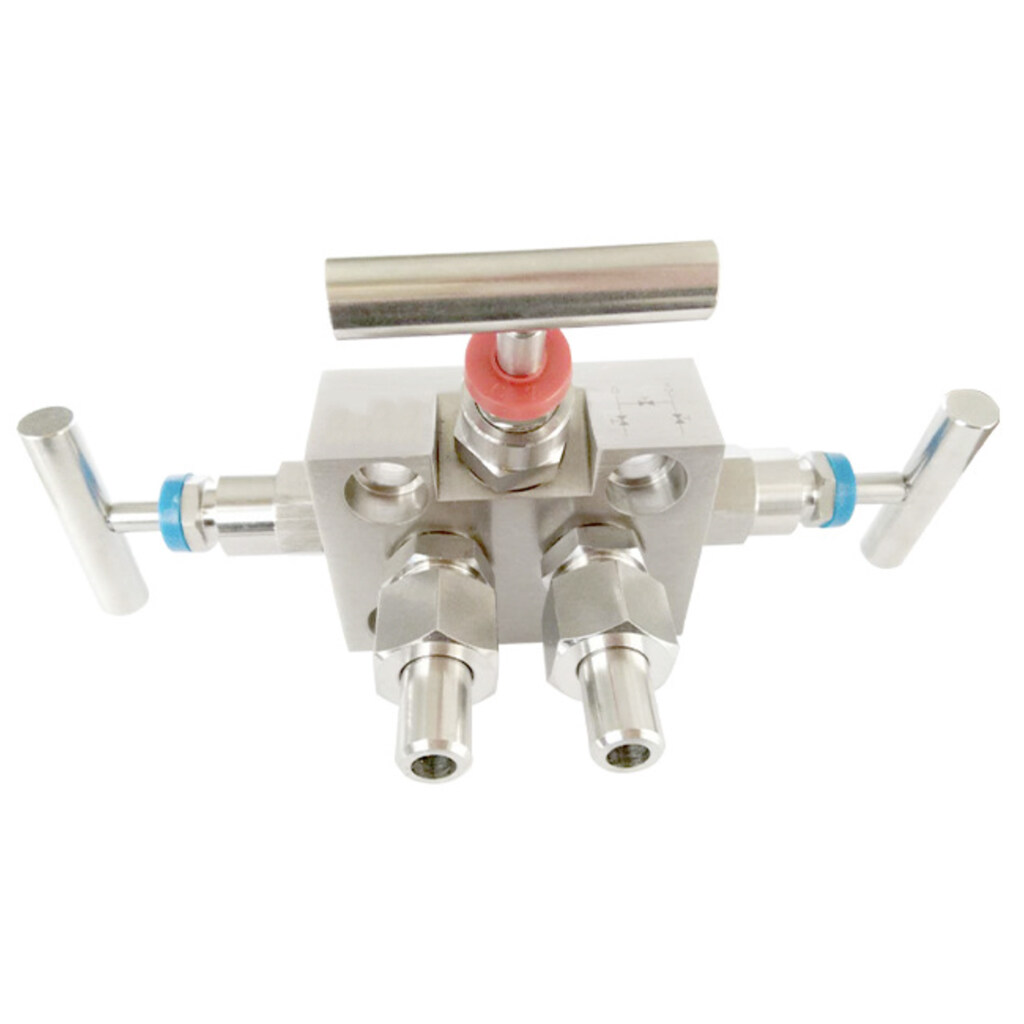

Internal thread mini stainless steel ball Valves globe Valves

Mini Stainless Steel Ball Valves with Internal Thread Manual valves include globe valves. The ball valve is a type of valve that achieves opening and closing by rotating a sphere with a circular tube that serves as the opening and closing component. The ball valve's opening and closing mechanism consists of a ball with a hole that rotates around an axis perpendicular to the channel to open and close the channel.

Internal Thread Mini Stainless Steel Ball Valves Globe Valves

Internal Thread Mini Stainless Steel Ball Valves Globe Valves are manual valves. The ball valve is a valve that uses a sphere with a circular passage as the opening and closing part, and the sphere rotates with the valve stem to realize the opening and closing action. The opening and closing part of the ball valve is a ball with a hole, which rotates around the axis perpendicular to the channel, so as to achieve the purpose of opening and closing the channel.

The advantages of Internal Thread Mini Stainless Steel Ball Valves Globe Valves

Ball valves are mainly used to cut off or connect pipelines and equipment media, and can also be used for fluid adjustment and control. Ball valves have small fluid resistance, simple structure, small size, light weight, tightness and reliability, easy operation and maintenance, and will not cause damage to the valve sealing surface. Erosion, a wide range of applications.

The maintainance of Internal Thread Mini Stainless Steel Ball Valves Globe Valves

1. Before use, clean the pipeline and valve body flow-through part with water to prevent residual iron filings and other debris from entering the valve body cavity.

2. When the stainless steel ball valve is in the closed state, there is still some medium in the valve body, and it is also under a certain pressure. Before overhauling the ball valve, close the shut-off valve in front of the ball valve, open the ball valve to be overhauled, and completely release the internal pressure of the valve body. If it is an electric ball valve or a pneumatic ball valve, the power and air source should be disconnected first.

3. When disassembling and assembling the ball valve, the bolts and nuts on the flange should be fixed first, then all the nuts should be slightly tightened, and then firmly fixed. If some nuts are forcibly fixed first, and then other nuts are fixed, the gasket surface will be damaged or broken due to uneven bearing between the flange surfaces, resulting in leakage of the medium from the valve flange.

4. If a slight leakage is found at the packing during use, the stem nut can be slightly tightened until the leakage stops, and no further tightening is allowed.